Team Airflow: Your Furnace, Air Conditioner & Duct System. Does the Duct System Matter?

Most homes in Colorado are heated by a central forced air furnace. Many also include a central air conditioner. Alone, the furnace or air conditioner is pretty much useless. But partner them with a properly designed central duct (or ducting) system to convey heated or cooled air to the rooms in your home, and you’re in business!

Delivering the correct volume of air plays a critical role in an effective and comfortable HVAC system. Let’s take a closer look at this important aspect, first with a brief explanation of the components of your duct system and then with an overview of how it can impact your day-to-day life.

What is a Duct System and Where is it Located?

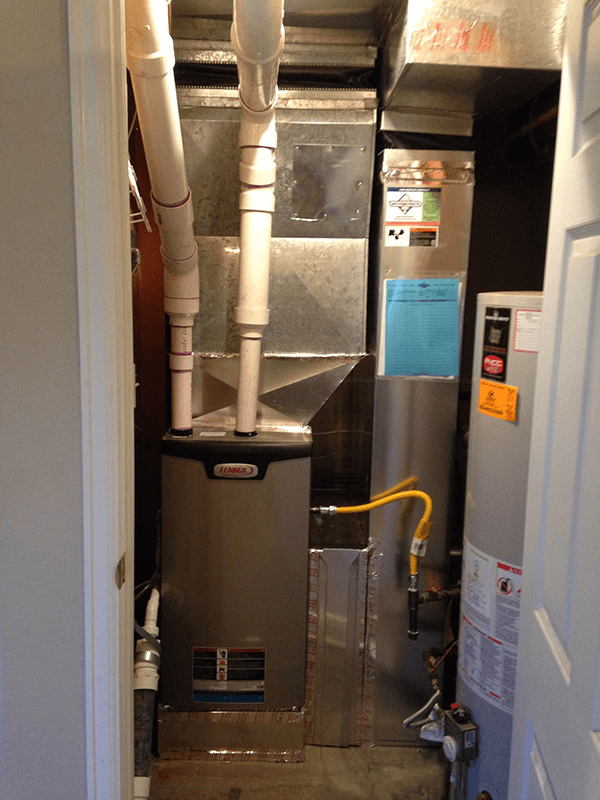

Your furnace includes a fan designed to move air throughout your home. Attached to most furnaces are large sheet metal ducts to convey that air. One branch of the duct system carries heated or cooled air away from the furnace and into the rooms of your home, while the other duct pulls air back to be reconditioned. Smaller pipes branch off the large main ducts to deliver air to the various rooms in your home. Often this duct system is hidden beneath the walls, floors and ceiling, with the only visible components being the grilles you see on floors, walls or the ceilings.

Most often, smaller grilles with adjustable dampers (supply registers) are used for the delivery of air while larger grilles without dampers are used for the air returning back to the furnace. Comparing your ducting system to a cardiovascular system would not be a stretch! Imagine the furnace blower acting as the heart, the main trunks as the arteries, and the smaller individual pipes as the veins.

In many homes, especially older ones, scant engineering went into the design of the ducting system. Often, where the furnace (heart) was located in the home, the size of the ducts (arteries), and where the smaller pipes (veins) were routed was dictated more by where they would fit, or where the builder would allow them to run, than by what was best for performance. Making matters worse, most HVAC contractors used rules of thumb and past experience rather than actual design parameters when determining how to install the ducting system. The importance of this cannot be understated! An HVAC system with design flaws is destined to struggle.

In many homes, especially older ones, scant engineering went into the design of the ducting system. Often, where the furnace (heart) was located in the home, the size of the ducts (arteries), and where the smaller pipes (veins) were routed was dictated more by where they would fit, or where the builder would allow them to run, than by what was best for performance. Making matters worse, most HVAC contractors used rules of thumb and past experience rather than actual design parameters when determining how to install the ducting system. The importance of this cannot be understated! An HVAC system with design flaws is destined to struggle.

Thankfully, for homes built in very recent years, most jurisdictions require that HVAC systems be designed and installed in accordance with specific engineering standards, including Manual D calculations, for duct system design, and Manual J calculations, for furnace and air conditioner sizing. These standards ensure that the heating and cooling equipment are just the right size to deal with the expected outdoor temperatures, and that each component of the duct system is sized to deliver the appropriate airflow to each room. Of course, it wasn’t always that way!

For existing homes, when replacing a furnace and/or air conditioner, a homeowner will want to confirm that their HVAC contractor has done a reliable Manual J calculation to size the replacement equipment. It is not to your advantage to just assume it will be fine to replace the old system with one of the same capacity, or especially, to assume that bigger is better. If you are advised that either of those is the way to go, look for another contractor! Proper sizing is critical.

Regarding the existing duct system, things get a little more complicated. In most cases the duct system is buried behind wallboard and under floors, meaning that duct system modifications could result in a more significant project than you are prepared to bite off. If your home is experiencing comfort issues, such as unacceptable hot or cold areas, or excessive noise, you should bring this to the attention of your HVAC service provider. A qualified contractor will be able to line out your options so you can make the best choice for your situation.

If nothing else, when updating your HVAC equipment, your contractor should carefully size the sheet metal ducting surrounding the furnace, including the incorporation of ‘turning vanes’ to lessen air restriction, and a properly sized air filter, all to ensure that the airflow specifications for your furnace and air conditioner are met. A contractor that will perform the calculations to properly size your furnace and air conditioner, and rebuild the duct system immediately surrounding your furnace to match that sizing, is worth their weight in gold (or at least in sheet metal)! It makes a huge difference, and not all contractors, whether high priced or low, understand its significance or are willing to put in the extra effort needed to accomplish this. It’s harder to achieve, but will make all the difference in the world for the homeowner!

What Does Airflow Affect?

So we’ve talked about the duct system and system design. But why are these things important?

Noise!

A smooth, unimpeded flow of air is critical for quiet operation of your forced air system. The less friction, or resistance to airflow, the quieter your system. Both a properly designed ducting system and a correctly sized blower motor in the furnace are important. Excess turbulence most anywhere in the system generates noise, and could possibly result in that ‘jet engine sound’ associated with some furnaces!

A note about fan speed: When annual service is performed on your system, consider asking the technician to test whether the fan speed is set at the proper levels for heating and cooling.

Reliability & Equipment Life

Air that flows fluidly can help avoid equipment failures. Consider these points:

- Good airflow puts less mechanical stress on the furnace blower and blower motor, helping them run as smoothly as possible, and reducing the chance of failure.

- Proper airflow allows components, such as temperature limits and igniters in the furnace, and the compressor in the air conditioner, to cycle less frequently, avoiding overwork of the part and extending its life.

- Proper airflow helps avoid frequent, wide temperature swings in the furnace’s heat exchanger, which could accelerate the aging process of that critical component. Not a cheap part to replace!

Comfort

Proper airflow will provide more uniform comfort, allowing conditioned air its best opportunity to reach all areas of your home. As stated earlier, most existing duct systems have some degree of imperfection to them since they were probably not ideally engineered. These design flaws will typically result in uneven temperatures that can range from mild to drastic.

If an imbalance issue can’t be adequately addressed by duct modifications, it might make sense to consider upgrading to two-stage or modulating furnaces and air conditioners, whose unique designs can assist in moderating temperatures in areas where airflow is less than optimum. These highly efficient and effective systems are worth a look, even if you have a great ducting system!

Heating Bills!

When air from a well-cared-for furnace or air conditioner is allowed to circulate effectively, the result will be optimum operating efficiency and lower heating bills. Electricity and gas will not be wasted as the system fights against restrictions, and the furnace will be able to do the best possible job for your family–and for your checkbook!

What Else Can I Do?

So far, this discussion has centered on the inherent condition of your ducting system. But there are some things you can do to optimize existing conditions. Here are a few suggestions that we hope will help make the most of your forced air system:

- Change the filter in your furnace regularly, and make sure that the filter you are using is not overly restrictive to airflow.

- Make sure that all air supply registers are open and that all return air grilles are unobstructed. Often, return air grilles are blocked by furniture, which is not to your advantage. Also be careful about covering floor registers with throw rugs.

- Periodically dust off the return air grilles and supply registers, which will help keep unwanted particles from finding their way into your respiratory system or furnace.

- Consider pulling up the floor registers (they’re typically not screwed down) and vacuuming any debris that may have collected in the sheet metal adapter right below the register. Sometimes those registers can be hard to get back in place, so if it’s snug, use your judgment as to whether to remove it.

Inspect the exposed sheet metal ducting in your furnace room, or anywhere else in the home where it’s accessible, to identify air gaps. If you see a joint that is not sealed, or a visible gap, seal it up. This can be accomplished using foil tape that can be purchased at most hardware stores. If there is any question about your ability to perform this work safely, or it’s just not your cup of tea, give your trusted HVAC contractor a call to assist.

For expert advice and service for your forced air furnace and air distribution system, in the Denver and Boulder, Colorado area, contact Save Home Heat Company!